Welcome to Our Company

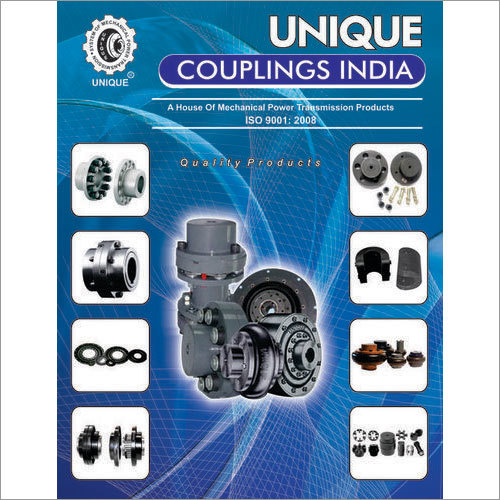

UNIQUE COUPLINGS INDIA

Product Details:

- Head Code Standard

- Sealing Rubber Elements / Synthetic Inserts Available

- Bore Pilot Bore / Finished Bore

- Torque Up to 30000 Nm

- Max. Speed Up to 4000 RPM

- Connection Clamp / Sleeve / Flanged

- Material Cast Iron, Mild Steel, Alloy Steel, Stainless Steel

- Click to View more

UNIQUE COUPLINGS INDIA Price And Quantity

- 10 Unit

UNIQUE COUPLINGS INDIA Product Specifications

- Rubber Elements / Synthetic Inserts Available

- Round

- Cast Iron, Mild Steel, Alloy Steel, Stainless Steel

- Standard

- As per Model, up to 480 mm

- Industrial Power Transmission, Machinery, Pumps, Motors, Compressors

- Phosphated / Blackodized / Zinc Plated / Painted

- Flexible Coupling

- ISI / DIN / ANSI / Customized

- Up to 30000 Nm

- Precision Machined

- Pilot Bore / Finished Bore

- Clamp / Sleeve / Flanged

- Up to 4000 RPM

- As per Specification, from 8 mm to 250 mm

UNIQUE COUPLINGS INDIA Trade Information

- 1000 Unit Per Week

- 10 Days

- Yes

- Contact us for information regarding our sample policy

- Carton Boxes

- All India

- ISO 9001:2008

Product Description

We are affianced in manufacturing, exporting and supplying highly flexible and resilient Unique Flexible Couplings to our esteemed clients. Our experts manufacture these couplings by making use of supreme quality raw materials and the contemporary techniques in accordance with the international quality standards. Used to reduce cyclic shocks of a driven shaft of the equipment, the provided couplings are used in diesel engine drives, fans, compressors, mills, rolling mills pumps, conveyors and dg sets. Further, we offer these Unique Flexible Couplings at highly competitive rates to the clients.

Features:

-

Require less maintenance

-

High flexibility

-

Robust construction

-

Easy installation

Unique Tyre Type Flexible Cushion Couplings

-

Highly flexible & resilient

-

Absorbs Large Misalignment

-

Low Torsional Stiffness

-

Dampens shock & Vibration

-

Flexible element easily replaceable.

-

Ideally suitable for Diesel Engine Drives, Fans , Mills , Compressors , Rolling Mills Pumps, Conveyors, DG Sets.

Available for reputed makes of Diesel

-

Engines & Compressors.

-

Custom Design for special requirements

-

Torsional Vibration Calculation on request

-

No lubrication, Minimum Maintenance

-

No expensive Downtime

Flexible element is made of rubber reinforced with Nylon Chords. Available in PH, PX, TC & U Series.

PH Series has largest range. These have flexible member firmly bolted to clamping elements .There is no possibility of Tyre slipping out even in case of imperfect installation.

Available for maximum torques up to 420000Nm. Coupling Tyre Diameter up to 1250 mm.

Versatile Applications and Customization

UNIQUE COUPLINGS INDIA offers flexible couplings engineered for a broad range of industries, including machinery, pumps, compressors, and motors. Available in multiple connection types such as clamp, sleeve, and flanged, they can be tailored to match specific application requirements and international standards like ISI, DIN, and ANSI. Custom benefits include a wide bore range and material options suited for demanding operational needs.

Sturdy Construction and Surface Protection

Each coupling is crafted using premium cast iron, mild steel, alloy steel, or stainless steel for enhanced durability. With surface treatments like phosphating, blackodizing, zinc plating, or painting, the couplings are built to resist corrosion and withstand challenging industrial environments. This ensures a long service life and consistent operational efficiency.

Precision Engineering for Reliable Performance

Our precision-machined couplings are designed to reduce vibration and ensure safe, efficient torque transmission. The flexible structure with optional rubber or synthetic inserts enhances system longevity and accommodates misalignment, delivering smooth performance even under high torque loads reaching 30,000 Nm.

FAQs of UNIQUE COUPLINGS INDIA:

Q: How do I choose the right flexible coupling for my industrial equipment?

A: Selecting the proper coupling depends on your applications torque, speed, bore size, and connection requirements. UNIQUE COUPLINGS INDIA offers expert guidance to match the right material, bore size (8 mm to 250 mm), and connection type (clamp, sleeve, or flanged) as per your machinerys specifications.Q: What are the main benefits of using your flexible couplings in power transmission?

A: Our flexible couplings absorb vibration, accommodate misalignment, and ensure efficient torque transfer up to 30,000 Nm. Quality materials and surface treatments provide durability and corrosion resistance, enhancing reliability and operational lifespan in various industrial setups.Q: Where can your couplings be used, and for which industries are they suitable?

A: UNIQUE COUPLINGS INDIA couplings are extensively used in industrial machinery, pumps, electric motors, and compressors across diverse sectors such as manufacturing, water treatment, and oil & gas, both in India and internationally.Q: What surface treatment options are available for your couplings?

A: We offer several surface treatments, including phosphated, blackodized, zinc plated, and painted finishes. These treatments improve corrosion resistance and extend product life, making them suitable for harsh operating environments.Q: How do your couplings accommodate different shaft sizes and standards?

A: Our products can be manufactured with pilot or finished bores, inner diameters as specified (8 mm to 250 mm), and outer diameters up to 480 mm. Compliance with ISI, DIN, ANSI, or customized standards ensures compatibility with a wide range of equipment.Q: What is the typical process for ordering custom couplings?

A: To order a custom coupling, provide your application details, including bore and shaft dimensions, torque, speed, preferred material, and desired standard. Our team will recommend the best solution and deliver precisely engineered products to your specifications.Q: What advantages do rubber elements or synthetic inserts offer in your couplings?

A: Rubber and synthetic inserts provide additional flexibility, helping to dampen shock loads and vibrations during operation. This not only protects connected equipment but also reduces maintenance needs and prolongs the lifespan of your machinery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS