Welcome to Our Company

Unique Nylon Gear Couplings

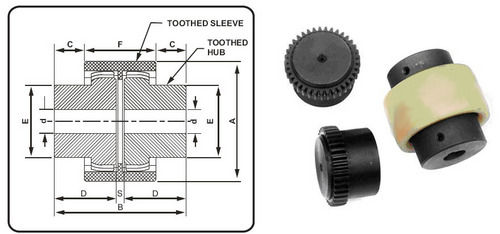

Product Details:

- Bore Precision Machined

- Head Code Standard

- Torque Up to 250 Nm

- Sealing No

- Max. Speed Up to 4000 rpm

- Connection Gear Type

- Material Nylon (Polyamide)

- Click to View more

Unique Nylon Gear Couplings Price And Quantity

- 100.00 - 1000.00 INR/Set

- 10 Unit

Unique Nylon Gear Couplings Product Specifications

- No

- Customizable (generally 40 mm to 150 mm)

- Customizable (generally 10 mm to 100 mm)

- DIN / IS / Custom

- Gear Type

- Nylon (Polyamide)

- Polished

- Injection Moulded

- Up to 4000 rpm

- Precision Machined

- Round

- Power Transmission, Machinery Connections, Motor and Pump Coupling

- Flexible Gear Coupling

- Up to 250 Nm

- Standard

Unique Nylon Gear Couplings Trade Information

- 1000 Unit Per Week

- 10 Days

- Yes

- Contact us for information regarding our sample policy

- Carton Boxes

- All India

- ISO 9001:2008

Product Description

With due perfection, we are highly engrossed in manufacturing, exporting and supplying Unique Nylon Gear Couplings that are known for their excellent surface finish. Our experts team manufacture these couplings by making utilization of supreme quality raw materials and the latest techniques at our well-equipped manufacturing setup. Quality tested on different parameters, these couplings are available in various sizes and finishes. Besides, we provide these Unique Nylon Gear Couplings at most economic rates to the clients.

Features:

-

Fine finish

-

Compact design

-

Easy to install

-

Robust construction

Dimensions and Technical Data

| Size | Rated | MaxBore | Pilor | KW 100 | Max. | A | B | C | D | E | F mm | S mm

| Weight | Inertia |

| M-19 | 16.6 | 19 | 10 | 0.17 | 11800 | 48 | 58 | 10.5 | 27 | 32 | 37 | 4 | 0.24 | 0.000042 |

| M-28 | 47 | 28 | 15 | 0.49 | 8500 | 66 | 84 | 19 | 40 | 44 | 46 | 4 | 0.86 | 0.00028 |

| M-38 | 84 | 38 | 15 | 0.88 | 6700 | 83 | 84 | 18 | 40 | 58 | 48 | 4 | 1.40 | 0.00078 |

| M-48 | 209 | 48 | 15 | 2.19 | 6000 | 100 | 110 | 28.5 | 53 | 65 | 53 | 4 | 2.38 | 0.00165 |

| M-65 | 380 | 65 | 25 | 4.00 | 4000 | 144 | 144 | 36 | 70 | 96 | 72 | 4 | 9.3 | 0.009 |

Reliable Performance for Diverse Applications

Engineered for robust power transmission, Unique Nylon Gear Couplings support a range of applications, from motor and pump coupling to machinery connections in industrial environments. Their versatility and flexible design ensure consistent performance even under demanding operational conditions.

High-Quality Material and Construction

Manufactured using high-grade nylon (polyamide), these gear couplings offer excellent wear resistance, smooth operation, and a polished surface finish. The injection moulding technique ensures dimensional accuracy and strength, making them suitable for heavy-duty usage.

Customization to Fit Every Need

The couplings are available in customizable bore and outer diameter ranges, accommodating specific requirements as per DIN, IS, or custom standards. This flexibility enables precise integration into existing or new machinery setups, ensuring optimal alignment and performance.

FAQs of Unique Nylon Gear Couplings:

Q: How are Unique Nylon Gear Couplings typically used in industrial settings?

A: These couplings are widely utilized for connecting power between motors and pumps or bridging machinery components. Their flexible gear structure effectively transmits torque while compensating for minor misalignments, making them suitable for various industrial applications.Q: What are the benefits of using nylon (polyamide) in gear couplings?

A: Nylon offers excellent wear resistance, low friction, and corrosion resistance, leading to reduced maintenance requirements, lower operational noise, and a longer coupling lifespan compared to traditional metal couplings.Q: When should I consider choosing a nylon gear coupling over a metal one?

A: Nylon gear couplings are ideal when you require low maintenance, quieter operation, and electrical insulation. They are particularly advantageous where moderate torque (up to 250 Nm) and high speeds (up to 4000 rpm) are involved, and chemical resistance is needed.Q: Where are Unique Nylon Gear Couplings supplied or exported from?

A: These couplings are distributed, exported, and supplied by various manufacturers, traders, and wholesalers across India. International orders can also be accommodated depending on the distributors export capabilities.Q: What is the process for customizing bore and diameter sizes?

A: Customers can specify the required bore and outer diameter dimensions within the available range (bore: 10-100 mm, OD: 40-150 mm). Manufacturers then use injection moulding and precision machining to deliver couplings tailored to the applications requirements.Q: Can these couplings handle alignment errors between shafts?

A: Yes, their flexible gear coupling structure is designed to accommodate minor angular, parallel, and axial misalignments, ensuring reliable performance and reducing stress on connected machinery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS