Welcome to Our Company

Unique Diaphragm Couplings

Product Details:

- Bore Customized

- Thread Not Threaded

- Torque Up to 8000 Nm

- Head Code Round

- Sealing Diaphragm

- Connection Flanged

- Max. Speed Up to 24000 RPM

- Click to View more

Unique Diaphragm Couplings Price And Quantity

- 1000.00 - 5000.00 INR/Set

- 10 Unit

Unique Diaphragm Couplings Product Specifications

- Round

- Flexible Coupling

- DIN/ISO

- Alloy Steel / Stainless Steel

- Up to 280 mm

- Diaphragm

- Up to 8000 Nm

- Not Threaded

- Customized

- Power transmission in various industrial machinery

- Machined

- Up to 180 mm

- Round

- Polished

- Up to 24000 RPM

- Flanged

Unique Diaphragm Couplings Trade Information

- 1000 Unit Per Week

- 10 Days

- Yes

- Contact us for information regarding our sample policy

- Carton Boxes

- All India

- ISO 9001:2008

Product Description

With the consistent improvisation of cutting-edge techniques, these Unique Diaphragm Couplings are perfectly manufactured by making use of best quality raw materials. The offered couplings are used in various applications like automotive, engineering, construction and other allied mechanical industries. Our quality experts rigorously check the provided couplings on different parameters in order to ensure their defect free delivery towards the clients end. We offer these Unique Diaphragm Couplings in different specifications at marginal rates to the clients.

Features:

-

Abrasion resistance

-

Accurate dimensions

-

Robust construction

-

Easy installation

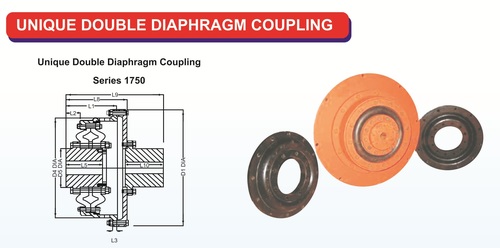

Unique Double Diaphragm Couplings Series 1000:

| Size VEZ | Max. Speed | Descriptions | D0 Max. | N mm | D7 mm | Weight Kg. | Inertia MR^2 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| CI RPM | CS RPM | L1 mm | L2 mm | L3 mm | L5 mm | L6 | L7 mm | D1 mm | D2 mm | D3 mm | CI mm | Steel mm | Inner Kg. m^2 | Outer Kg. M^2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Unique Diaphragm Type Flexible Couplings

- Highly Flexible and resilient

- Low Dynamic Torsional Stiffness

- Torsional Stiffness varies with Load

- Isolates and dampens Torsional Vibration

- Ideally suitable for Diesel Engine Drives ,Compressors ,Rolling Mills , DG Sets Pumps

- Available for reputed makes of Diesel Engines & compressors.

- Custom Design for special Requirements

- Torsional Vibration Calculation on request

- No Lubrication . Minimum Maintenance

At nominal torque torsional angle is large - typically 10 to 15 degrees. Torsional Stiffness is low. This results in low critical speeds , usually below operating speed. Further torsional stiffness varies with load. At lower loads stiffness is lower. The Feature allows operation at wide range of speeds.Favourable damping charactistics ensure vibration amplitude are limited at resonance.

Precision Engineering for Industrial Applications

Our diaphragm couplings are meticulously engineered using machined techniques to ensure high performance and reliability in demanding power transmission applications. The polished finish and use of top-grade alloy steel or stainless steel deliver corrosion resistance and longevity, making them suitable for various industrial sectors.

Customizable Designs for Enhanced Versatility

We offer diaphragm couplings with customized bore dimensions and round head codes to meet specific requirements. The flexible structure, flanged connection, and seamless sealing with diaphragms ensure secure and efficient operation, adaptable to different machinery and installation parameters.

Compliant with International Standards

All our diaphragm couplings meet DIN/ISO standards, guaranteeing consistent quality and global compatibility. The products design supports high torque and speed capabilities, making it a preferred choice for critical industrial power transmission needs.

FAQs of Unique Diaphragm Couplings:

Q: How do Unique Diaphragm Couplings enhance power transmission in industrial machinery?

A: Unique Diaphragm Couplings provide flexible yet robust connections, efficiently transmitting torque up to 8000 Nm and handling speeds up to 24,000 RPM. Their machined, flanged construction minimizes misalignment and vibration, improving operational stability and machine longevity.Q: What surface treatment and materials are used in manufacturing these couplings?

A: These couplings undergo a polished surface treatment for corrosion resistance and are crafted from high-quality alloy steel or stainless steel. This ensures durability and superior mechanical performance even in harsh industrial environments.Q: When should diaphragm couplings be used in machinery setups?

A: Diaphragm couplings are ideal in applications requiring high-speed, high-torque power transmission with flexible misalignment handling. They are particularly useful in situations where vibration reduction and sealing integrity are crucial, such as in compressors, turbines, and pumps.Q: Where can Unique Diaphragm Couplings be sourced in India?

A: These couplings are available across India through reputable distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers, ensuring easy procurement for industrial clients nationwide.Q: What is the process for customizing the bore and dimensions of these couplings?

A: Customers can specify their required bore dimensions, shapes, and material preferences. Each coupling is precision-machined to meet custom specifications, adhering strictly to DIN/ISO standards for performance and compatibility.Q: How are flanged connections and diaphragm seals beneficial in these couplings?

A: Flanged connections provide secure, reliable joint strength, while the diaphragm seal ensures leak-proof and maintenance-free operation. This design maximizes coupling efficiency and minimizes downtime in industrial settings.Q: What benefits do these couplings offer over threaded or rigid alternatives?

A: Compared to threaded or rigid couplings, diaphragm couplings offer superior flexibility, vibration damping, and compensation for misalignment. Their round shape and flanged, non-threaded construction simplify installation and boost overall machinery safety and efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS