Welcome to Our Company

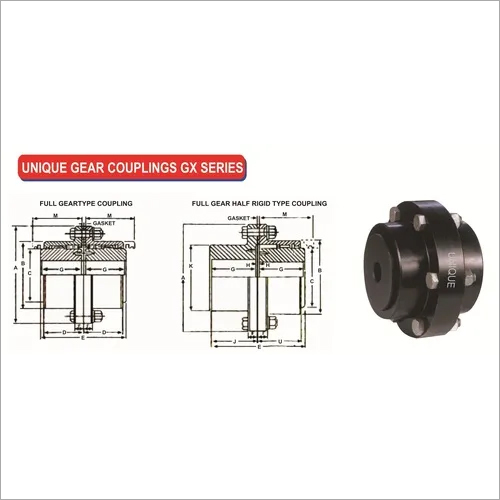

UNIQUE GEAR COUPLINGS

1000.00 - 10000.00 INR/Unit

Product Details:

- Connection Flanged/Keyed

- Head Code Standard

- Max. Speed Up to 4500 rpm

- Sealing O-ring/Grease Sealed

- Bore Pilot, Finished, or Custom Bore

- Torque Up to 260,000 Nm

- Material Forged Alloy Steel, EN8/EN9/C45 or as required

- Click to View more

X

UNIQUE GEAR COUPLINGS Price And Quantity

- 1000.00 - 10000.00 INR/Unit

- 10 , , Unit

UNIQUE GEAR COUPLINGS Product Specifications

- IS 6112, AGMA, DIN

- Power transmission in industrial machinery, conveyors, pumps, compressors, and rolling mills

- Round/Cylindrical Coupling Shape

- Up to 260,000 Nm

- Blackodized, Anti-corrosive coating

- Flanged/Keyed

- Precision Machined

- 40 mm to 850 mm (Customized)

- Standard

- Up to 4500 rpm

- 20 mm to 400 mm (Customized)

- Double Hub with Sleeve and Hardened Teeth

- Forged Alloy Steel, EN8/EN9/C45 or as required

- O-ring/Grease Sealed

- Pilot, Finished, or Custom Bore

UNIQUE GEAR COUPLINGS Trade Information

- 1000 , , Unit Per Week

- 10 Days

Product Description

Select from the potent range of UNIQUE GEAR COUPLINGS, meticulously crafted to achieve in-demand performance across industrial sectors. Last Chance to avail decorated, valorous couplings engineered for power transmission in conveyors, compressors, and rolling mills. With a shot blasted or painted finish, surface hardened teeth (5060 HRC), and dynamic balancing, these couplings offer superior misalignment capacity and robust anti-corrosive protection. Enjoy easy maintenance, replaceable seals, and a vast size range from GC 100 to GC 1400trusted by distributors, exporters, manufacturers, and suppliers throughout India.

Features and Competitive Advantage

UNIQUE GEAR COUPLINGS feature precision-machined, forged alloy steel construction with blackodized and anti-corrosive coating. The material enhances durability while surface hardened teeth deliver reliability under high torque and misalignment. With full gear, half gear, and rigid options, their versatile design fits demanding industrial machinery. Compliance with IS 6112, AGMA, and DIN standards ensures trustworthy quality, making them a competitive choice for power transmission and dynamic balancing in high-speed applications.

Sample Policy and Payment Guidelines

Samples of UNIQUE GEAR COUPLINGS can be arranged upon request, subject to applicable outlay and rate. Packing & dispatch adheres to industry protocols guaranteeing safe delivery. Payment terms are flexible and transparent, designed for wholesalers, traders, and retailers to facilitate hassle-free transactions. This supportive sample policy enables you to evaluate the couplings fit and performance before bulk procurement, fostering reliable partnership and confidence in your purchase decision.

Features and Competitive Advantage

UNIQUE GEAR COUPLINGS feature precision-machined, forged alloy steel construction with blackodized and anti-corrosive coating. The material enhances durability while surface hardened teeth deliver reliability under high torque and misalignment. With full gear, half gear, and rigid options, their versatile design fits demanding industrial machinery. Compliance with IS 6112, AGMA, and DIN standards ensures trustworthy quality, making them a competitive choice for power transmission and dynamic balancing in high-speed applications.

Sample Policy and Payment Guidelines

Samples of UNIQUE GEAR COUPLINGS can be arranged upon request, subject to applicable outlay and rate. Packing & dispatch adheres to industry protocols guaranteeing safe delivery. Payment terms are flexible and transparent, designed for wholesalers, traders, and retailers to facilitate hassle-free transactions. This supportive sample policy enables you to evaluate the couplings fit and performance before bulk procurement, fostering reliable partnership and confidence in your purchase decision.

FAQs of UNIQUE GEAR COUPLINGS:

Q: How do UNIQUE GEAR COUPLINGS handle misalignment in machinery?

A: UNIQUE GEAR COUPLINGS are designed to accommodate up to 1.5 angular and 4 mm parallel misalignment, ensuring smooth and efficient power transmission even when components shift during operation.Q: What industries typically use these gear couplings?

A: These couplings are widely in demand for industrial machinery, conveyors, pumps, compressors, and rolling mills, supporting heavy-duty applications requiring high torque and dynamic balancing.Q: When should seals be replaced for optimal performance?

A: Seals should be inspected regularly and replaced during routine maintenance or whenever signs of wear, leakage, or reduced lubrication efficiency are detected, ensuring consistent coupling performance.Q: Where are UNIQUE GEAR COUPLINGS manufactured and supplied?

A: They are manufactured in India and supplied nationally and internationally through authorized distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers.Q: What is the process for ordering customized sizes or bores?

A: Contact the supplier with specific requirements for inner or outer diameter, bore type, or surface treatment. The production team will confirm customization options and provide details on lead times and cost implications.Q: What benefit does dynamic balancing provide in high-speed applications?

A: Dynamic balancing ensures stable operation, reduces vibration, and extends gearbox lifespan, especially when gear couplings are used in machinery running at up to 4500 rpm.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS